Quali punti obbligati intermedi ai due estremi esigano particolari riguardi per non essere trascurati, ma che anzi siavi tutta la convenienza di toccarli con la strada, come sarebbe qualche piccolo villaggio od altro sito in qualche modo abitato, qualche tratta non tanto acclive e sulla quale possa esservi condotto un miglior tratto di strada di più facile costruzione ed uso per cui risulti conveniente di approffittarne, quelle tali località scevre da pericoli di valanghe od altro che puonno ritenersi le più atte per stabilirvi le case Cantoniere e i casini pei lavoratori e rompitori delle nevi; punti tutti essenziali da coltivarsi di maniera che fra gli uni e gli altri di questi vanno a costituirsi tante tratte di studio parziale da tracciarsi e svilupparsi fra i propri singolari estremi.

Carlo Donegani

The exhibition 'Carlo Donegani Ingegnere. La Strada dello Stelvio 1820 - 1825. Storia e prospettive di valorizzazione' (Carlo Donegani Engineer. The Stelvio road 1820 - 1825. History and prospects for enhancement), is an opportunity to bring to attention a great infrastructural heritage built two centuries ago for military reasons. A road that has taken on the contours of myth since its beginnings because of the difficult feat of tackling the mountain at altitudes never reached before, up to the point of lapping the glacier tongue at the height of the Stelvio yoke. For many years, it was the highest carriageable pass in Europe. It was the engineer Carlo Donegani who launched the 'impossible challenge' with a project that was very daring for the time, the result of extraordinary technical skills, of an accurate knowledge of the mountains in impervious valleys, dotted with landslides, avalanches and steep watercourses to penetrate what was considered pure wilderness, original nature. It was a complex orography that Donegani, in just five years, surveyed in detail and tackled in terms of design and construction, designing a road with all its equipment, which he brought to completion by working in the summer months alone. An approach in which the small measurements of the repeated cross-sections, survey, and design, complete with their architectural equipment, punctually outline a relationship with the large dimension of the valley through the overall development of the overall chorography.

But the road comes to life and gives new life to a fascinating but historically hostile environment, where few people dared to pass in preference to other and different paths, soon becoming a tourist attraction, commercial transit, a place of wars and ambushes, of car, motorbike and bicycle sporting challenges, eventually acquiring the name 'Cima Coppi' for the heroic feats performed by Fausto Coppi along its climbs.

A complexity of life that over time has consumed and transformed the road itself and its profound relationship with the place in the name of greater road usability, new technical data and presumed safety standards, and indiscriminate tourist access, the result of a partial, heterogeneous, and segmented approach, even when animated by generic good intentions of valorisation. What remains and in what condition is that heritage today?

It is clear from these first words that the road and the valley with its mountains and histories are a single and inseparable landscape, environmental and anthropic entity. It is from this angle that we are interested in drawing attention to the richness and risks of this heritage. A heritage that in engineer Donegani's project took up the challenge of the need for a unitary conception, taking the extraordinariness of the technical datum as an opportunity to reread it in its broader value of the relationship between intelligence and man's effort in comparison with the beauty and strength of nature.

The final objective is now to try to reread its history and the conditions of its composite and articulated topicality in order to define a project perspective of overall and strategic valorisation of the road and the valley. A great project that once again takes up today the challenge that Donegani had the courage to face two hundred years ago: that of restoring an overall, unitary yet multidisciplinary vision. In this sense effectively polytechnic.

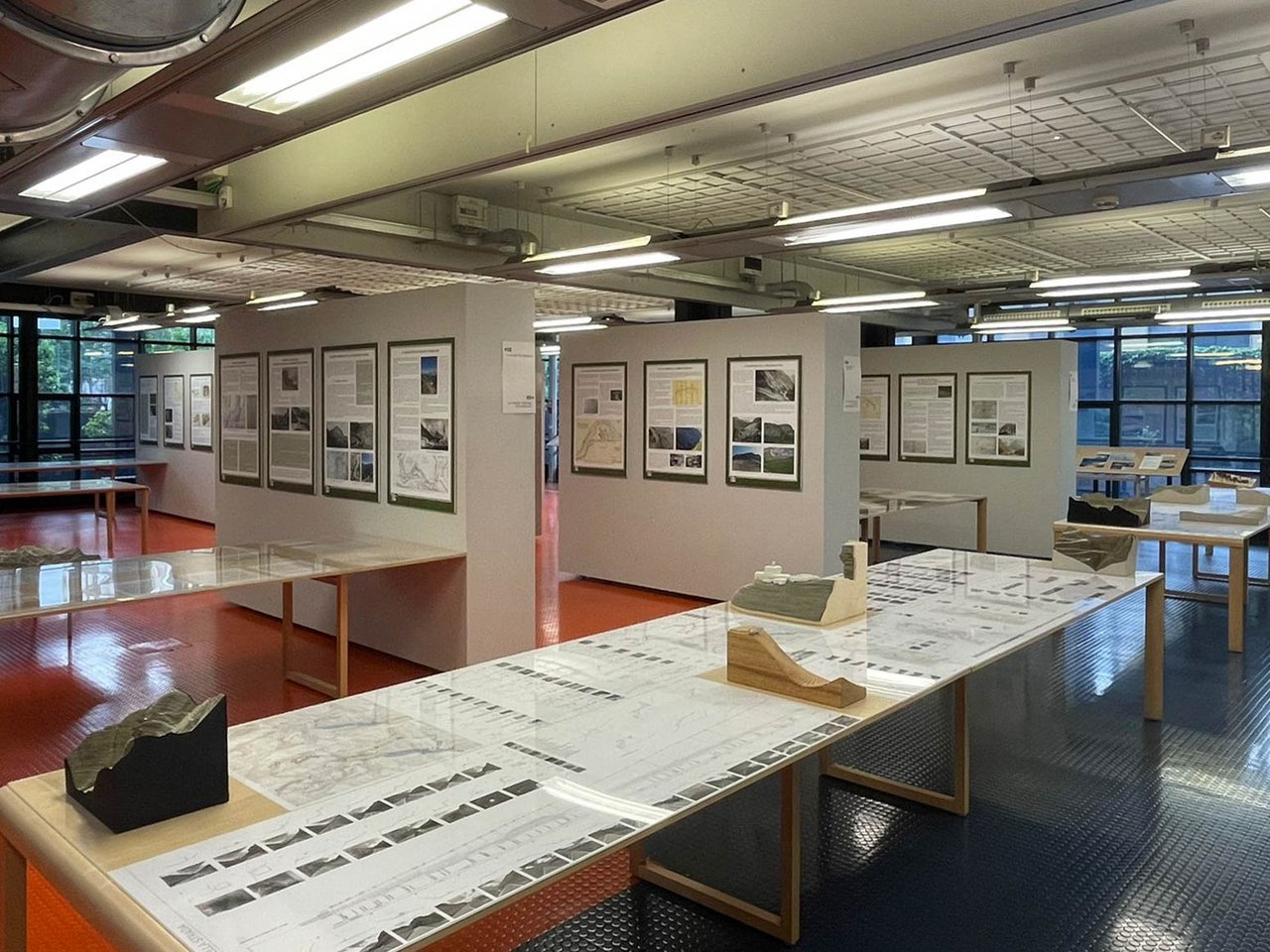

The exhibition consists of two parts. A historical one that brings together a previous experience carried out by the Donegani Documentation Center set up within the Carlo Donegani High School (now part of the Sondrio City High School). Since 1998, the Center has acquired over 150 original plates (plans, sections, profiles) relating to the design of the Stelvio, Spluga and Aprica roads, planned in the early 19th century by engineer Carlo Donegani. Works that still today constitute the pivot of the mountain road system in the province of Sondrio.

The richness of the documentary fund constitutes the basis of the 'Donegani Project', a multi-year programme involving teachers and high school students that over the years has been variously modulated to investigate significant design aspects, to be contextualised with the contribution of archival research.

This exhibition presents a selection of the work carried out by students from the Liceo Donegani and IIS Alberti high school in Bormio, coordinated by Maria Carla Fay with the contribution of Cristina Pedrana, a scholar of historical routes, on the Stelvio Pass road (Lombardy and Sud Tirol parts); this is complemented by a selection of panels resulting from the previous study dedicated to the Spluga Pass.

The research led to an in-depth study of original works of art, artefacts and construction techniques, allowing the design choices to be read in the light of the historical and geomorphological context. The result is the exceptional character of these works, a true "impossible challenge" taken on and won by Carlo Donegani.

A second part consists of a mapping and analytical reading of the current conditions and design scenarios that consciously interpret the relationship between small and large dimensions, proposing an overall strategy for the enhancement of the road and the valley. A work realised between 2017 and 2018 in the final third-year Laboratory of Design and Furnishing of Open Spaces conducted by Michele Ugolini, Caterina Gallizioli and Francesco Occhiuto at the School of Architecture Urban Planning Construction Engineering of the Politecnico di Milano and carried out in connection with the Stelvio National Park of the Lombardy Region. The focus was in the first year the Braulio valley, from Bormio to the pass, and in the second year it expands to the lateral connection with the Cancano lakes and the nearby Fraele pass.

The analytical path is subdivided into two phases, one of knowledge of the places and general themes, the other more explicitly dedicated to interpretative themes of a state of art that the project aims at. A design strategy that deals synergistically with the different themes in a logic of the whole, not of separate parts. With this in mind, the sections of the road that have been abandoned and have fallen into disuse and ruin over time are linked to portions of the paths that run in fragments along the valley to be projectually connected by new sections to design an alternative pedestrian route from Bormio to the pass, a route that does not exist today, which plays and intertwines in its longitudinal linear relationship with the road - approaching and receding from its structures: drystone retaining walls, bridges reinterpreted from below in unprecedented perspectives, tunnels - rather than with the course of the stream with its waterfalls, gorges and bends that allow one to approach the water. The idea is substantiated that the road and its relationship with the nature of the valley reveal their close and inseparable relationship in being seen from outside the road itself: "the road outside the road."

The reconnaissance of abandoned artefacts, not only the most obvious ones, Case Cantoniere, wartime artefacts or the piles of collapsed bridges, old, partially submerged dams, but also all those apparently less noble remnants and fragments that remained scattered and half-hidden in the territory after the construction of the Cancano dams, or the fruit of old activities linked to pastoralism, reveal unseen potential, opportunities for reconnection through the paths to larger systems, unexpected points of reinterpretation of the landscape.

A mountainous area known for its natural beauty as witnessed by the beautiful views drawn by the Swiss painter J.J. Meyer in 1831, but which in the last two centuries has become a place heavily infrastructured: the road with its hairpin bends, the high-tension power lines with their pylons interpreting the emerging points of the orography, the system of water conduits feeding the Cancano lakes with their dams and power stations. Nature, infrastructures, and human history intertwine in a story that cannot be separated but needs a gaze that gathers and reveals the intimate nature that inextricably links them in order to relaunch new readings and new design perspectives.

1.

What is the presumable vertical elevation to be conquered starting from the inferior obligatory point to reach the preferable point on the summit which, by custom presents itself with some depression at the junction of the dominant valleys in which the first sources arising from the drains of the highest glaciers collect, and which gradually swelling constitute the principle of the two longitudinal rivers of the opposite valleys.

2.

What is the presumable base of each valley or slope on which the elevation as above proximately known is to be won, in order to know under what acclivity in the ratio of each hundred it would be developed in the hypothesis of conducting a straight line of a single level, and therefore what greater length it would need in the event that the above proportion exceeds the limit that will have been established for maximum in the relevant program.

3.

What obligatory intermediate points at the two extremes require special care not to be neglected, but rather that there is every convenience of touching them with the road, as would be some small village or other site in some way inhabited, some tract not so steep and on which there may be conducted a better section of road of easier construction and use for which it would be convenient to take advantage of it, those such localities free from danger of avalanches or other which may be considered the most suitable for establishing Cantoniere houses and lodges for workers and snowbreakers; all essential points to be cultivated in such a way that between one and the other of these go to form so many partial study routes to be traced and developed between their own singular extremes.

4.

Having established the above, it is necessary to know the respective mountain slopes that form the sides of the valley, along which the road must be traced in order to note the most avalanche-prone areas, so as to avoid them as much as possible, and in particular to ensure that their crossing with the new road will not be repeated in the event that it is necessary to practice some kind of tourniquets in the vicinity, which is achieved by establishing the turnaround before reaching the dangerous location, and thus after the lower turnaround crossing it only, while otherwise taking the upper tourniquet beyond that to turn again and having to return to cross it again on the continuation of the line, one would cross it three times without purpose.

5.

The choice of the most convenient sites for the tourniquets is also a very important subject of study, while it is not so easy to obtain along the uphill slopes that are almost always not very inclined, the reduction of a transversal plane for the turnaround from the diameter to a width that is required from 14 to 16 metres, not less, which sometimes leads to the need to increase or decrease the slope of the arm to reach the aforementioned most suitable location, and here it is appropriate to observe that in the drawing of each of the arms of the road that descend in the opposite direction of the natural slope of the valley, these must be assigned a lesser slope than the other two that descend according to it, in order to avoid the optical deception that occurs when comparing the other arms of making these intermediate arms appear almost doubly inclined; this regard must also be taken into account in establishing the rest planes and in particular the longitudinal plane of the road where it crosses rivers or valleys with bridges, not neglecting to conserve on the same a progressive inclination never less than approximately one third of that assigned to the road level to be interrupted in such flat stretches observing from experience that with such progressive inclination the apparent appearance of horizontal is obtained by comparison, while otherwise establishing these sections as truly horizontal as would seem to be required by the quality in question, or even with a slope less than the aforementioned proportion, they inevitably present the deformity of wrong construction, i.e., executed not horizontally but inclined in the opposite direction.

6.

The choice of the aforementioned squares for the tourniquets and the number of them depends on the operator's most expert eye in order to consume the slope of each section with the least possible elongation of the line, however, as much as is sufficient for the development, having in mind that some sections that are less steep than the ordinary slope assigned in the programme, and even almost flat, are very important to reduce the fatigue especially of the ascending draught animals, almost always making sure that on mountain roads there is no loss of slope with very wide horizontal planes that give the idea of a counter-slope, as has been observed, and to avoid positive counter-slopes as far as possible.

7.

Let the operator not be dismayed if, in his search for the line with the level under such an inclination as is prescribed for him as a maximum, he should bump into some considerable protrusion of living rock or if he should find that the slope of the mountain has changed into sheer rock, would be forced to think about tunnel perforations and not be dismayed in situ, since this type of work, in addition to being reduced in the day to the minimum terms of its positive expenditure of execution, reunites the advantage of not presenting any work that would require an expense for its conservation in progress, remaining in all to the mere and pure maintenance of the paved career as it is found to be the most convenient covered parts. With such perforations, which are almost generally parallel to or not far from the outer wall and can easily be illuminated by frequent openings called windows, many difficulties are overcome that at first glance seem insurmountable, and this in the most obvious way, in addition to offering the passenger occasional shelter in the event of bad weather and free from danger from any other fortuitous event of rock or lava landslides that are so frequent in mountainous sites.

8.

Since such unavoidable accidents of sheer rock to be overcome, landslide sites to be avoided, sites to be chosen for tourniquet, etc., must be discovered by the operator at the greatest possible distance from his work in order to regulate the progress of levelling with the aim of reaching the former in less difficult points to avoid the latter with possible line divergences. the operator must discover them at the greatest possible distance from his work in order to regulate the progress of levelling with the aim of reaching the former in less difficult points to avoid the latter with possible divergences of line, adopting the same approach even if it is necessary to pass from one bank of the valley to the other, and thus to take advantage as much as possible of the aforementioned thirds, i.e. to better position the tourniquets, cases or other, it is very useful to search for the line with the level starting from the top, descending and not from the bottom, ascending.

9.

Since the operation of levelling, which must serve as a trace for the consecutive planimetric survey of the line and its lateral circumstances, can only result in an irregular course that must then be adjusted with better lines brought together with graceful curves that are always weighted in the best way that the natural course of the slope being traversed can allow, it should be noted that the cross-sections that must be taken at each of the stakes that serve as stations or purposes for levelling, are generally extended on both sides of the relative picket, in which way, having delineated the profile of the levelled ground and known the irregularity of the line described by the picket resulting from the levelling, it is obvious to regularise it as it is found to be most appropriate with the operations of the table, thus not lacking any relative data.

From Giovanni Donegani, Guida allo Stelvio, 1842

NEWS ON THE WORKING METHOD USED IN THE EXECUTION OF THE DRILL TUNNELS

The name of tunnel is particularly given to that perforation of vaulted rock that, in the execution of a road project, the counsels of art and a well-considered economy suggest to adopt in order to make the very career of the road run inside it. This perforation work, which is carried out with the work of the miners, embraces two distinct parts, that is, the work of advancing and the work of cutting the bottleneck.

Given the cross-section of a tunnel with a width of 5 m and a height of 5 m, or should we say with a surface area of approximately 22 m², the work of advancing the tunnel is limited to the drilling of the first 2.5 m of the radius of the vault, and in general to the drilling of the vault itself from the shutters to the top. The cutting of the bottleneck (thus naming the remaining portion of rock from the shutters to the bottom of the tunnel) forms the work known as excavation.

In advance work, as the most important, costly and difficult, the employment of skilled miners is required. In excavation work, because it is much easier, and almost equal to open-cut rock, less experienced miners are employed.

No breakthrough work shall commence unless the advance work is buried at least six metres of escape, ensuring that the space between the two workings is sufficiently large, and remains approximately so until the end of the drilling so that other miners can be stationed there.

The advance work is carried out with shallow mines, applied in as many directions as the head miner's intelligence deems most appropriate to the natural direction and the partial circumstances of the rock to be drilled, so that the tunnel vault will be regular and will not exceed the established dimensions. The cutting of the bottleneck or excavation is carried out in two cuttings or steps as seen in figure A, and the material from all the work is continuously gathered at the foot of the last cutout, and then transported elsewhere.

The drilling of a tunnel is usually begun at the two ends of the mouth and the outlet, and continued until the opposing companies of miners meet; bearing in mind that when they are at a short distance from each other, it is advisable to oblige them to narrow the work, or let's say to make them advance only in the centre, and this in order to be able to correct without great difficulty and without making the error that by chance may have arisen from not having followed the fundamental line exactly very noticeable.

No more than seven pairs of miners may be employed in each tunnel mouth of the above-mentioned dimensions, all together called a company, always directed by a leader, whose skill must consist in knowing the course of the veins and the quality of the rock to be cut in order to be able to judiciously indicate the places where the mines are to be applied and the direction to be given to the mine hole itself. When the tunnels exceed a length of 50 metres on each side, two or more daily service men should be attached to the said pairs, as required, and continuously employed in the transport of the material. As the drilling progresses, however, a few assistants are added to provide light for the operators.

Miner's pairs are made up of two individuals, each of whom now beats, now holds the mould, and very rarely, and in the cutouts alone, a third is also paired to beat. Three pairs, and as was said, the best are employed in the advance, the other three are divided on the cutouts of the choke.

This being the case, and assuming that the rock to be drilled is sound, the result of the work of all the aforementioned workers, which is generally piecework, i.e. by invoice, in each week of six active days, can hardly exceed one linear metre of finished gallery, taken for the appropriate length of day, and considering that the continuous labour of each company in the summer is never less than twelve hours, and eight hours in the winter.

The tools used by the miners are as follows:

- The mould

- The dredge

- The mallet

- The rasp or brush

- The mallet or small hammer

- The livera

- The mace

- The boron or loader

- The baton or gucchia

- The mould is a round iron rod steeled at both ends and terminated at the bottom with a cutting edge shaped like an ancient axe. The dimensions of the moulds range from 0.30 m to 1.25 m in length and from 0.016 m to 0.025 m in thickness.

- The dredge is also a round iron rod, terminated at the lower end with the mould and is approximately 1.80 m long and 0.025 m thick.

- The mallet used to beat the mould is an iron hammer of parallelepiped shape with rounded corners, weighing approximately 3.00 kg, attached to which is a wooden handle.

- The rasp or brush is an iron rod no more than three millimetres thick with a kind of round spoon at the lower end, with a diameter of between 0.012 and 0.020 metres. Each company of miners needs two of these rasps, one about 0.60 metres long and the other about 1.30 metres. These strokes are used to remove the dust generated by the work of the mould and dredge from the mine holes.

- The mine hammer or small pick-hammer terminates at one end like other hammers and at the other with a point. Its weight does not exceed 1.00 kilogram and it is used to break off small rock protrusions left by chance by the mine from the walls and vault of tunnels.

The ‘livera’ is a round iron rod, terminated at both ends like a chisel, about 1.50 metres long and about 0.04 metres thick, which is used to move large boulders.

The mace, which weighs approximately 5.00 kg, is used to break boulders that cannot be moved with the livera.

The boron or loader is an iron rod, also round, with a small groove on one side in the vertical direction, which serves to hold the stick. The borons are 0.60 to 1.00 metres long and 0.012 to 0.020 metres thick, and even these require two per company.

The iron rod or gucchia is 0.60 to 1.20 metres long and about 2 millimetres thick. The upper end ends in a ring and the lower end ends in a tip. Each company needs two. It should be noted that the iron constituting all the above-mentioned strokes is of hard quality. The holes for the mines are drilled with moulds, which can be deepened to 1.00 metres or more. The dredge is usually only used for vertical holes that are to be drilled beyond the common length of the mould. When the dredge is used, it ceases the use of the mallet which the miners use to beat the mould into the rock. Since the dredge is of a reflexible weight, it is used with four arms to lift it up and drop it gradually into the holes already appropriately initiated by the mould. Both the mould and the dredge are made to rotate with each stroke in the hole so that the hole is round.

The mould and the dredge, if they do not break by accident, last a very long time, as only the steel is worn at both ends, which is always put back on after tempering.

On the other hand, the hammer is no longer usable after about a week's continuous work, so it must be boiled again and the necessary quantity of iron added to make it approximately the same weight as before. The moulds are tempered more or less according to the hardness of the rock. To make it easier to drill a hole as deep as 0.60 metres, the drillers, after having deepened the hole by about two decimeters, place a little water in it, thus avoiding the formation of dust underneath the mould or the dredge, which would delay the work considerably. Experience has also shown that when the rock is sound, it takes each pair of miners about four hours to drill a hole a little more than 0.60 metres deep. Often, when drilling a mine hole, and before reaching the specified depth, a layer of quartz, or a so-called Liscione or rock of a more compact nature than the first, is encountered, forcing the mould to deviate from its direction. In this case, since it is necessary for the hole to always be kept straight, and since there is no remedy for this inconvenience, the miners cease working at once, and content themselves with loading and firing only the portion that has been made. They tend to do the same when the mould encounters a crack. Having completed the mine holes, one of the experienced miners sets about loading them. This operation, which requires much practice and diligence, is performed as follows. A little more than the first third of the hole is filled with powder, then the rod or gucchia is introduced, then a small layer of clay or paper or teppe, or even dry rubbish from the same mine, above which and for almost all the remaining height of the hole, sand or clayey earth or scrap metal is placed, taking care to beat them and compress them well with the borrone, after which the gouache is extracted and the fuse is introduced into the hole left by it. The fuse is made up of several small sticks of paper rolled up in the shape of a cone, on the surface of which is spread a crayon of powder dissolved in water, wine or urine. A piece of bait about 0.12 metres long is attached to the top of the fuse, to which the fire is then applied. When loading the mines, the operator must take care to avoid death by not inserting the rod to the bottom of the mine itself, and to take care that it does not drop down while the wad is being struck, since by accident a vein of quartz or siliceous stone may be found at the lower end of the hole which, when rubbed or struck with any force, will instantly produce an explosion. It would therefore be praiseworthy if instead of an iron rod a copper one were used, although it is easier to bend, or at least if the loaders were careful to place a roll of paper or rags in the hole before the powder, but unfortunately they take few precautions. It can be assumed that each hole requires about four milliard ounces of powder. When the necessary holes have been drilled in the advance or in the mould or both, then, in order not to waste time, they are loaded and fired. The loader numbers the explosions of the mines in order to know if all have gone off or if any do not catch fire, after the necessary time has elapsed to consume all the bait attached to the fuse, the same loader is taken to visit and fire again.

[1]Sondrio State Archive, AsS Fondo Donegani Bs II file 5.2 undated and unsigned. The handwriting is that of Carlo Donegani.

-

Seminar's flyer

PDF

-

Exhibition's flyer

PDF